Testing Your Patch Cord Performance Before Plug-in, a Smart Way to Reduce the Risk of Your Network.

Patch cords play an important role in cabling systems and data centers, providing flexibility for moves and changes to the network. To ensure their function and speed transmission work in real field network cabling, having test program is a typical procedure to check. Therefore, there are two different ways to examine the patch cord performance: Channel Test and Component Test.

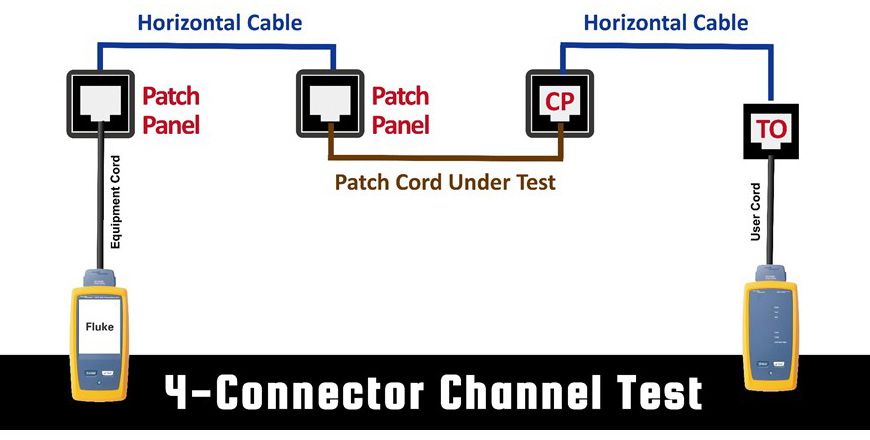

Channel Test

"Channel test" is the whole combined cabling circuit and chained with patch cord, wall plate, horizontal cable, patch panel, and patch cord. The maximum length for this combined cabling circuit is 100m. To imitate the real field cabling system, testing the whole channel performance and transmission speed. If the circuits' result is a "pass" which are suitable for network deployment. Following the below chart, four connector channel test sets up in cabling environment.

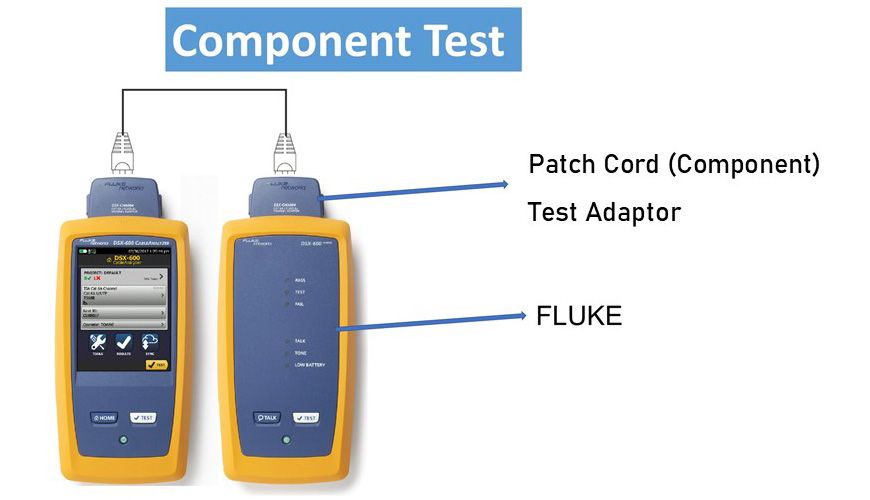

Component Test

Generally speaking, the component test is to examine the patch cord itself, which is also referred to as Unit Testing or Module Testing. Compared with the channel test, a component test is a much stricter measurement because it refers to the stand-alone components. For individual components, these standards specify mechanical requirements, physical characteristics, and performance parameters such as frequency, insertion loss, return loss, and crosstalk. If all components in a channel are component compliant, the channel should also be compliant-unless they were subjected to poor installation practices. Following the chart below, only one patch cord end to end on adaptors sets up called component test.

Conclusion

These testing requirements are designed for high speed networking and data center applications. In these applications, a faulty patch cable or cabling circuit may result in network or data center which may lead to a significant financial loss. Therefore, with test program to ensure patch cord performance and physical characteristics is a basic and necessary procedure. Hopefully, by this article you may keep it as a suggestion to get your ideal patch cords in practices.

CRXCabling strives to bring extra level of quality is by component level testing of our keystone jacks and field termination plugs to extremely strict ANSI / TIA 568-D.2 guidelines. If you have interest in more information, feel free to contact us.

- Download

Testing The Patch Cord Channel vs Component Test

A Basic Guide of Copper Patch Cord Test Method with Fluke Cable Analyzer: Patch Cord Test or Channel Test, and how to choose them for your project.

Solution Provider of Telecom

Developing future-oriented products that meet high standard of needs; offering versatile end-to-end copper and fiber cabling solutions to increase business success around the globe.

Advantage

High-Quality is Our Policy Ensure the quality and safety of goods. Acquire telecom insights to stay in front of trends. Regulate and provide series cabling solution service. Read More